First, Let's see some Geomembrane installation suggestions:

1. Before cutting, there should be an accurate measurement of its size, and then according to the actual dimensions to cut, cutting should not be commonly according to the size of the drawing list, should number each piece.

2. Try to weld the least, on the premise of guarantee quality, as far as possible to save raw materials. At the same time easy to ensure the project quality.

3. The geomembrane and Geomembrane between the lap joint width is generally not less than 15 cm, usually made of weld direction parallel to the maximum gradent, namely along the gradient direction.

4. Usually in a corner and deformity location, should be seam length shorten as far as possible. In addition to the special requirements in the slopes of the slope is greater than the 1:6 is apart from the top of slope or stress concentration area within the scope of 1.5 meters, as far as possible without welds

5. HDPE liner Geomembrane in laying, should avoid to produce artificial fold, the temperature is lower, should try to tighten, paving

6. HDPE liner Geomembrane laying is completed, should reduce as far as possible to walk on the surface of the Geomembrane, move tool, etc., all can cause harm to HDPE Geomembrane, all should not be on the Geomembrane or walking to carry on the Geomembrane, so as not to cause accidental damage to the film

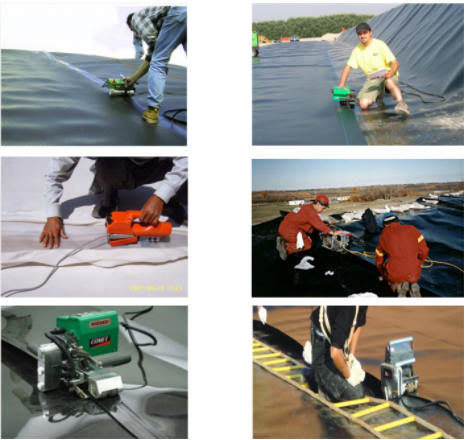

Geomembrane welding

There are 13 steps to teach you how to weld the HDPE Geomembrane liner:

1. The hot cheese welder welding process can be divided into adjusting the pressure, setting temperature, setting speed, lap welding seam inspection, Geomembrane into the machine, starting the motor, and pressure welding.

2. Seams can not have oil, dirt, HDPE Geomembrane lap Duan Mian should not with sediment and other sundry when have clutter must be cleaned before welding.

3. The welding at the beginning of a day, must try welding at the scene of a 0.9 mm x 0.3 mm sample, lap width is not less than 15 cm, and the peel and shear test, tensile machine field sample after qualification, and available when the velocity, pressure, temperature is adjusted welding. Need to indicate the date, time, and environment temperature on the sample. Heat is woven in the welding process, welding machine at any time attention should be paid to the running situation of the welding machine, according to the actual situation of the fine-tuning of the velocity and temperature.

4. The weld requirement is neat and beautiful, and it can not have the phenomena of welding, jump away.

5. When confronted by the length of the Geomembrane is not enough, needs to be joined together longer, should the transverse weld first, and then weld the longitudinal seam, the transverse weld is greater than 50 cm apart should T word, may not cross.

6. Adjacent Geomembrane welding seam should be staggered joints lap, film is formed between nodes, should be T word, as far as possible to reduce cross, longitudinal mode to weld extrusion welding strengthen intersection point application.

7. No pressure from death when welding the Geomembrane, laying HDPE Geomembrane, according to local variations in temperature and HDPE Geomembrane performance requirements, set aside telescopic deformation caused by temperature change.

8. When the temperature of the portable welding machine control controlled by welding temperature below 200 ℃, with a clean cloth or cotton dust and welding, when necessary to burnish, hand brush try to avoid it by all means.

9. When the joint condensation, moisture, sediment, etc, is processed after welding.

10. Or seam moisture during rain, dew, or under the condition of big sand cannot be welded, except to take protective measures is.

11. The temperature is below 5 ℃, and should not be constructed in accordance with the specification requirements if must constructed, for welding machine preheating before welding processing.

12. The extrusion welding machine in the welding process, should check the slider of the spear, which should change in time when the slider with severe wear, so as not to damage the Geomembrane surface.

13. The geomembrane in the generator power supply voltage regulator should be used when welding good performance, in special cases using local power, a voltage regulator must be used.

If you have any questions want to know more.

Contact us directly!!!

1. Geosynthetics Clay Liner, HDPE Liner,Geomembrane, Geotextiles, Drainage Systems, Geonet used for Landfill industry.

2. Geocell,Geoweb, Geogrid used for Erosion Control Projects.

3. Pavement Geogrid, Geonet, Rockfall Netting, and Geotextiles fabrics used for earthwork projects or the mining industry.

4. GCL, Geotextile, Bi-plannar geonet, dewatering geotube, Silt Curtain used for Environmental Projects.

can not be empty

can not be empty