Geotechnical materials are geosynthetic materials that are widely used in geotechnical engineering today. It is a general term for polymer products.As early as the 1920s, the chemical industry successfully produced synthetic materials, but it was not until the late 1950s that this material was gradually popularized as a new type of building material and applied to geotechnical engineering.The early products were mainly permeable woven and non-woven geotextiles, and later impermeable geomembranes were produced.With the requirements of engineering practice and the improvement of manufacturing technology, geogrid and other combined products for high-strength reinforcement have been manufactured one after another.

But how much do you know about the production of geotechnical materials?

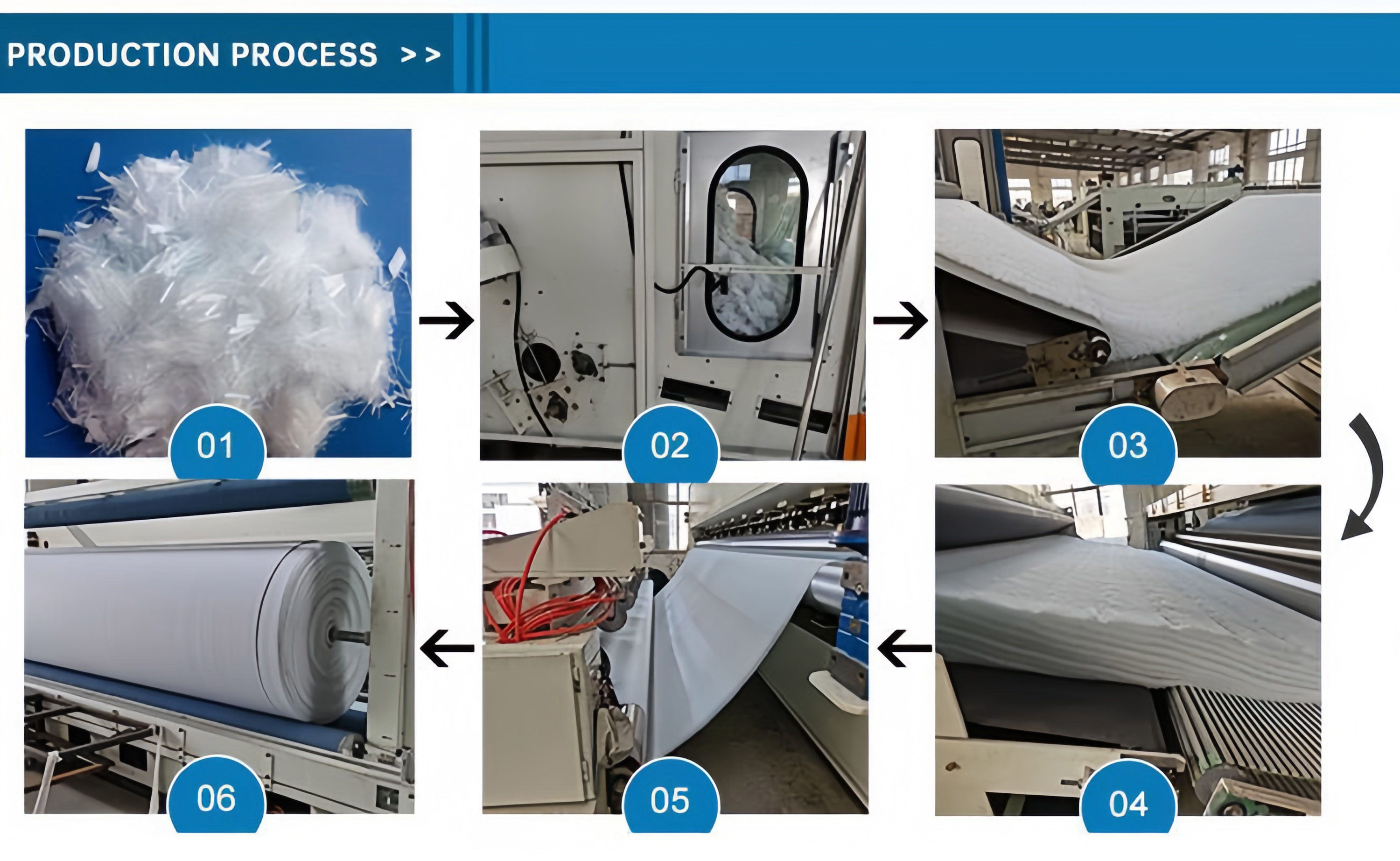

1. Non-woven geotextile production process

Needle-needle non-woven fabric is a kind of dry non-woven fabric.The staple fibers are loosened, combed and laid into a fibrous mesh, and then the fibrous mesh is reinforced into a cloth with a needle.The needle has a hook, the fiber mesh is repeatedly pierced, and the hook is strengthened to form a needle-punched nonwovens.The detailed description is made of polyester and polypropylene raw materials, combed, combed, pre-acupuncture, and main acupuncture.The center is sandwiched with a mesh cloth, and then after two-channel verification, the air flow is formed into a mesh and acupuncture is combined into a cloth. The filter cloth has a three-dimensional structure. After heat setting and singeing, the surface is most treated with chemical oils to make the filter cloth smooth and the micropores are evenly distributed. From the surface, the density of the product is good, the surface on both sides is smooth and the degree of breathability is good. The use of filtration on the plate and frame compressor proves that high-strength pressure can be used, and the filtration accuracy is as high as within 4 microns. Two raw materials, polypropylene and polyester, can be provided according to user needs.

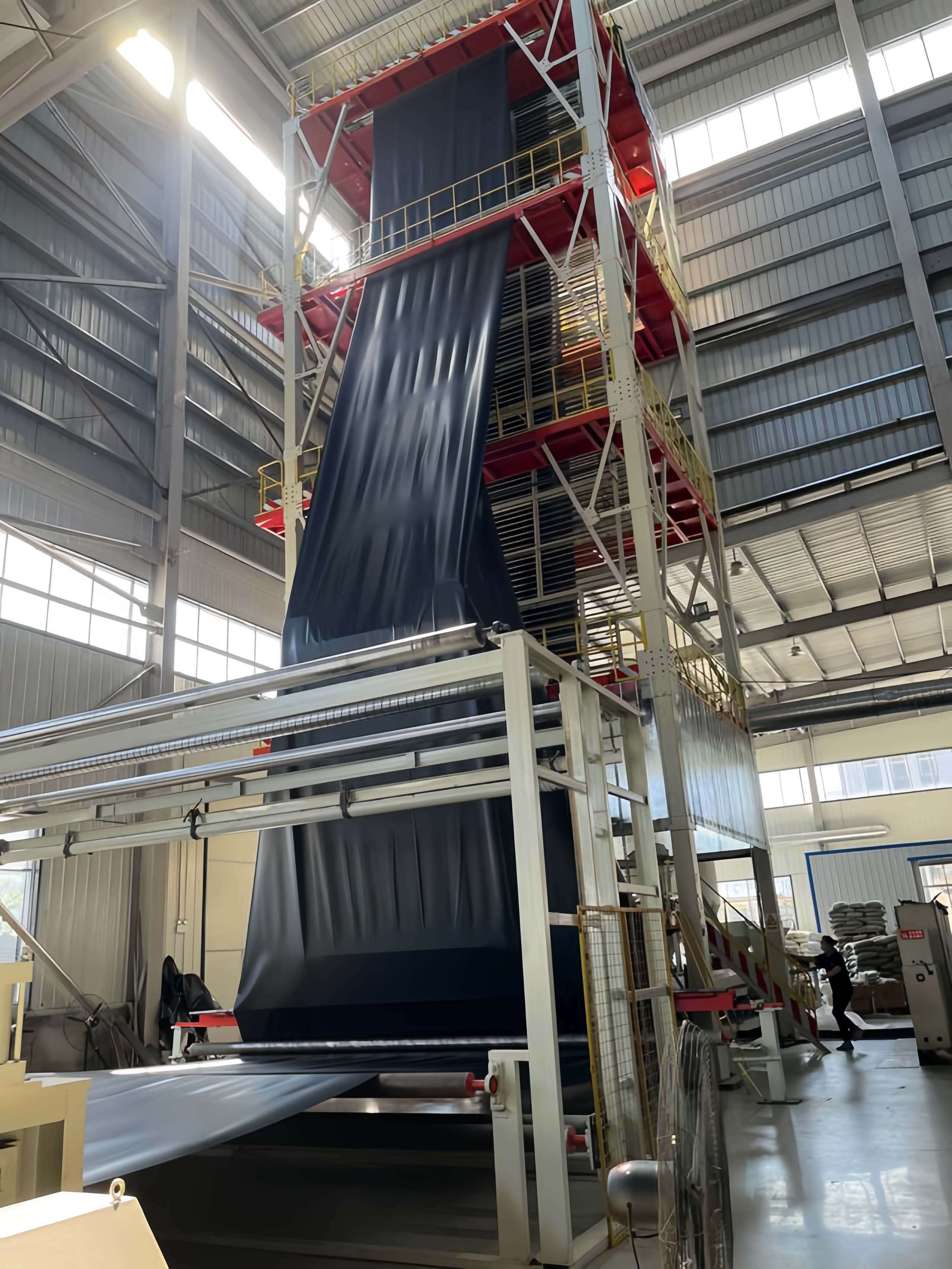

2.HDPE geomembrane production process

Generally, there are two types of geomembrane production processes, laminating and calendering process and blow molding process. The thickness specifications are commonly used in (0.2mm~3.0mm), and blow molding can be 0.03mm.The film thickness size of the blow molding process is more stable than that of the calendering process, and some urban construction indicators with strict engineering indicators are produced in the blow molding process.

1) Rolling process production process

The high-density polyethylene (HDPE) particles, masterbatch, carbon black, (if necessary, add anti-oxidation, anti-ultraviolet and double anti-UV agents) are dried and mixed evenly under high pressure in accordance with a certain proportion, and then extruded by a high-temperature melting screw, multi-layer co-extrusion is rolled into a film by a steel machine roller or a rubber roller, the corresponding size is cut out, and the volume is measured.Generally, the film thickness below 0.8mm (80 wire) with a relatively thin film thickness is rolled out by rubber rollers, and the surface brightness is worse than that of steel rods.

2) Blow molding process production process

Generally, it is a three-layer co-extrusion blow molding. The raw materials are transported to the die head of the blow molding machine through three heating screws. The heating and melting are formed into a cylindrical shape at the head position. The compressed air is blown upward through the die to form a film bubble of a certain size and diameter, which is cooled by the traction air and divided into a roll by traction measurement on the film display rack.

3. Production process of Geosynthetics Clay Liner

1. Sodium-based bentonite is coated; the upper and lower geotextiles are made of non-woven fabrics and woven fabrics, and sodium-based bentonite is added between the two layers of geotextiles.

2. Acupuncture and compounding: A acupuncture machine is used to pass the needle through the upper geotextile, sodium-based bentonite and the lower geotextile. The needle barb scrapes off the upper geotextile fiber, and the fiber is left between the two geotextiles after the needle is returned to complete the acupuncture and compounding.

3. Gluing: Apply a layer of light-curing glue to the lower geotextile of the exposed fiber thread.In a dark environment, the light-curable adhesive quickly solidifies after receiving ultraviolet light, forming a layer of light-curable adhesive film, which forms a four-layer waterproof blanket.

HUATAO GROUP

Add: No.298, Zhonghua North Street, Shijiazhuang city, Hebei, China.

Tel: +86 18032422676 (WhatsApp & Wechat)

E-mail: annie.lu@huataogroup.com

Website: https://www.htgeosynthetics.com/

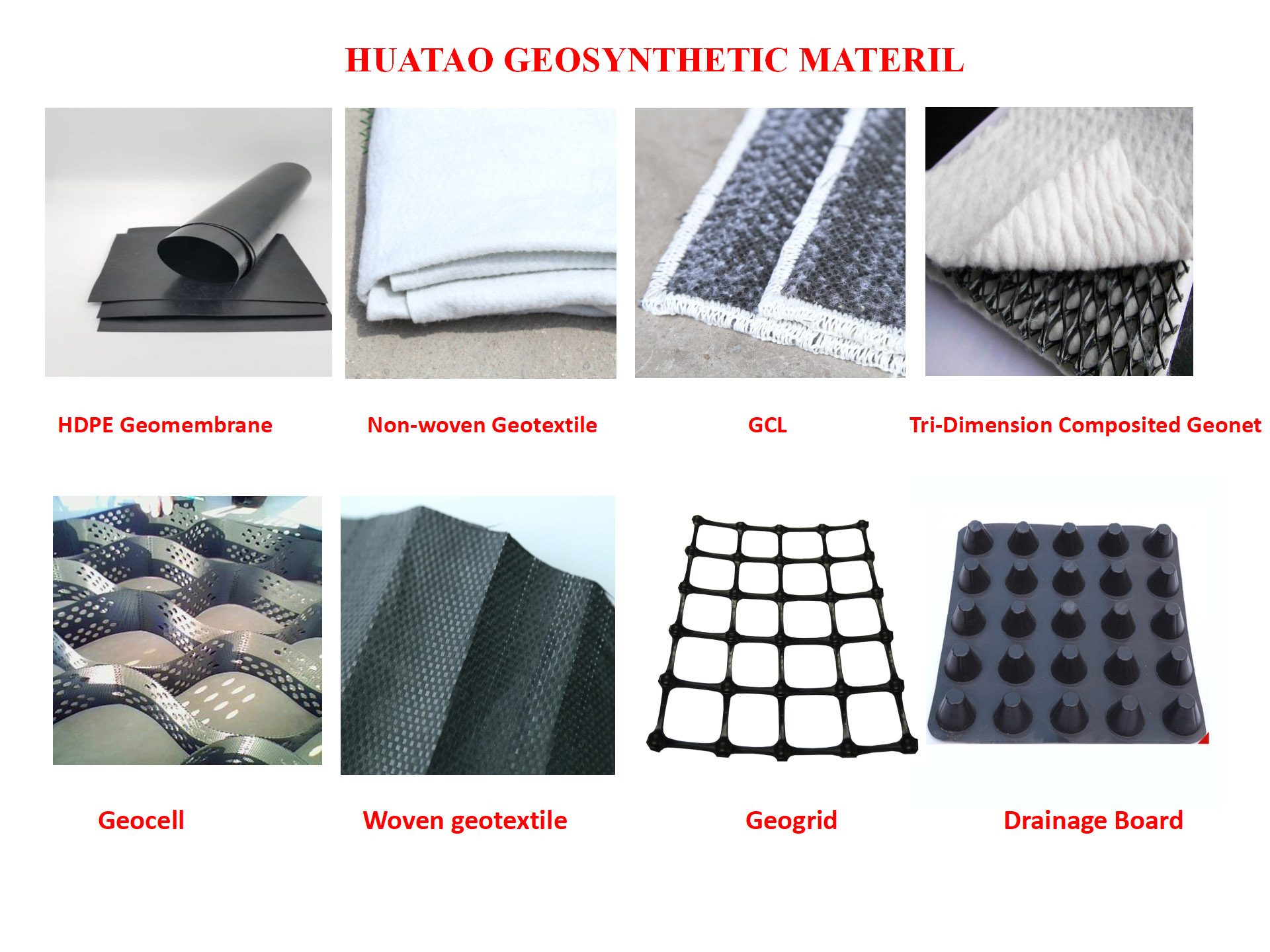

*** Huatao Mainly Products***

1. Geosynthetics Clay Liner, HDPE Liner,Geomembrane, Geotextiles, Drainage Systems, Geonet used for Landfill industry.

2. Geocell,Geoweb, Geogrid used for Erosion Control Projects.

3. Pavement Geogrid, Geonet, Rockfall Netting, and Geotextiles fabrics used for earthwork projects or the mining industry.

4. GCL, Geotextile, Bi-plannar geonet, dewatering geotube, Silt Curtain used for Environmental Projects.

can not be empty

can not be empty