Non-woven geotextiles are an important part of industrial textiles, and they play an important role in the field of geotechnical construction on a global scale.With the continuous expansion of the application range of geotextiles and the complexity of the application environment, high-performance geotextiles with high strength and multi-function have become the development direction of geotextiles.China's geotextile production enterprises and related scientific research institutions focus on the development of key materials and core technologies of high-performance geotextiles, so that the performance of high-performance geotextiles in terms of weather resistance, functionality, strength, etc. can be further improved, while reducing costs and increasing production capacity.

Part1: How much do you know about the classification of non-woven geotextiles?

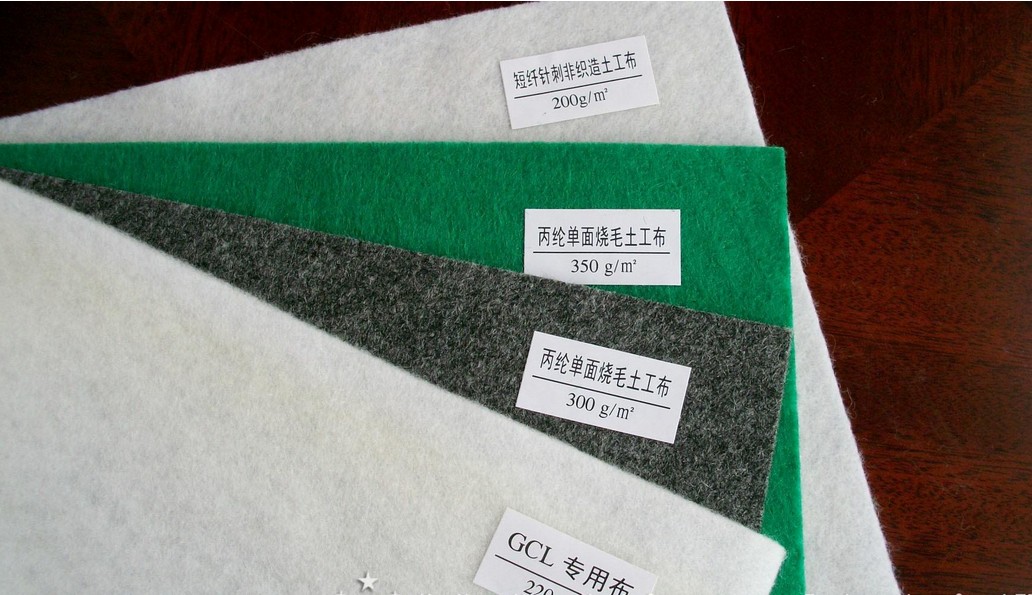

1.According to the different production processes, geotextiles can be divided into three categories: woven geotextiles, needle-punched geotextiles, and composite geotextiles.

2.According to the different raw materials, geotextiles can be divided into two categories: PP non-woven geotextiles and PET non-woven geotextiles.

3.According to the length of the fiber, the geotextile can be divided into two categories: filament geotextile and needle punched geotextile.

The non-woven geotextile has high production efficiency, good extensibility, mechanical properties and horizontal osmotic filtration properties.Composite geotextile has more advantages than the first two types of geotextile. It is composed of two or more geotextile or geotextile-related products. It has better overall performance and is a kind of high-performance geotextile that is widely used in various projects. A class of high-performance geotextile.

Part2: How to choose the raw materials for non-woven geotextiles?

The choice of raw materials for non-woven geotextiles must match the actual needs of the project, and the performance requirements of the geotextiles on site must be considered as well as the cost of the product.The raw materials for the production of geotextiles are currently mainly PP and PET.Among them, PP is currently used the most, while PET's alkali and corrosion resistance is not as good as PP, and its use in geotextiles is second only to PP.Of course, the cost of PET will be much higher than the cost of PP.However, when it is necessary to produce high-performance geotextiles, additives are usually added to improve the performance of geotextiles, such as antioxidants, light stabilizers, ultraviolet absorption stabilizers, long-term heat stabilizers, processing modifiers, flame-retardant agents, lubricants, antibacterial agents, etc.

Part3: What are the applications of non-woven geotextiles?

1. Application in the field of road construction

In the process of road construction, non-woven geotextiles are added between the granular stone layer and the soil layer of the road to isolate the soil layer from the granular stone layer, allowing water to flow upward but preventing the soil from flowing through, which can play a role in diverting water to the drainage system, thereby extending the life of the road by 3-5 times.At the same time, it relies on the interfacial friction between the geotextile and the surrounding soil to limit the lateral movement of the soil and increase the carrying capacity of the soil, thereby improving the integrity and structural support capacity of the soil and the building during use.In addition, the use of geotextiles for reinforcement on temporary roads or construction platforms can effectively improve the problems faced by construction such as too soft soil, thereby reducing the thickness of gravel required for construction equipment to enter the site and maintaining the stability of the subgrade.

2. Application of landfills

Under normal circumstances, the ground of the landfill site will be covered with a geotextile filter layer to prevent congestion of the leachate collection and drainage system.Geotextile is used to control the gradient of the head of the interception ditch, which can control the water level at the bottom of the landfill.At the same time, avoid the lower or upper geomembrane being pierced.In landfills, the role of non-woven fabrics can be summarized as protection, diversion, isolation, and filtration.

3. Application of coastal and river construction

Geotextiles are often widely used in coastal revetment, seawall construction, and land reclamation projects.When the fine material soil layer flows into the coarse material soil layer, the good breathability and water permeability of the non-woven geotextile are used to make the water flow through, and the soil particles, fine sand, small stones, etc. are effectively cut off to maintain the stability of water and soil engineering.

For example, the water and capillary phenomena in the dam will cause damage to the dam, and the laying of non-woven geotextiles can withstand the impact of surging waves and undercurrents, thereby greatly improving the life of the dam.In addition to being used for rivers and reservoirs, this method can also be used for coastal protection.Therefore, the hydro-mechanical properties and durability of geotextiles have become essential.

HUATAO GROUP

Add: No.298, Zhonghua North Street, Shijiazhuang city, Hebei, China.

Tel: +86 18032422676 (WhatsApp & Wechat)

E-mail: annie.lu@huataogroup.com

Website: https://www.htgeosynthetics.com/

*** Huatao Mainly Products***

1. Geosynthetics Clay Liner, HDPE Liner,Geomembrane, Geotextiles, Drainage Systems, Geonet used for Landfill industry.

2. Geocell,Geoweb, Geogrid used for Erosion Control Projects.

3. Pavement Geogrid, Geonet, Rockfall Netting, and Geotextiles fabrics used for earthwork projects or the mining industry.

4. GCL, Geotextile, Bi-plannar geonet, dewatering geotube, Silt Curtain used for Environmental Projects.

can not be empty

can not be empty